The Pilgrim Precision

Design and Build

The Pilgrim Precision begins to take shape…

First thoughts, strangely, centred around a 1000cc v-twin. At this time I had half an eye on the saleability of the bike which I was considering building in limited numbers (I have since revised this plan and this is definitely no longer the case…) and I had a view of the positioning that the bike would need to carry a premium price. I also had a funny idea at the time that around 100bhp would be a good starting point (!) I originally thought about a JAP (Prestwich) 1000 or 1100 and a few other options then settled on the idea of taking a 1200cc Buell Thunderbolt (45 degree, unit construction Harley Sportster making 103bhp) and re-packaging it into a new crankcase at 50 degree cylinder angle, with new barrels and heads to boot. This would run through a non-unit Quaife 5-speed box.

The basic idea was that the bike had to be good for motorways and dual-carriageways (even a Sunday afternoon run around the lanes could quite possibly end with a blast back up the motorway). My own distant memories of abandoned cars and bikes on the hard shoulders of Britain’s newly-emerged motorways of the 1960s and 70s and delving into the road tests and other records of pre-motorway engine preservation techniques were a salient reminder that pre-motorway engine design wasn’t really up to this. (“When travelling at speed, turn your head to 90 degrees every few minutes to listen for tell-tale changes in engine note and at around 5 mile intervals remember to back off for a while to cool down the piston crown…” etc, etc)

Anyway, long story short, (too late for that I know) I found myself out at Daytona during bike week riding an old M-Series (2011) Triumph Thruxton in glorious sunshine, bare-headed with a loud pipe and decided there and then that a big v-twin was unnecessary madness. I was already well-aware that with modern tyres, brakes and other essential changes from the 1920s the bike was going to have to deal with significant up-grades in terms of component strength and obviously chassis stiffness and a huge lump of a motor knocking out something the other side of 100 horse-power was moving so far away from the British flat tanker premise that the original goal had become meaningless.

I decided that around 60bhp would be fine, and an all-up weight of around 115kg wet would be a good target to aim for.

The JAP 1100

The Buell 1200

I actually re-packaged the entire Buell internals and made the first half of the 1200cc, 50 degree crankcase before changing tack!

500cc single is the way to go

That got me firmly set on the idea of a 500 single. After dabbling with the idea of starting with a JAP speedway engine or looking closer at a re-engineering of something from the period I settled on Patrick Walker’s 500 DOHC Manx Norton race engine…

Overhead cam engines were already firmly taking the lead in racing by the mid-twenties and on the road soon after that. DOHC was a stretch though if I was to remain true to period and myself and Patrick did discuss the idea of an SOHC Norton Inter arrangement but it was Patrick’s contemporary re-engineering of the internals and his race-proven reliability that I was after… and so DOHC it would be.

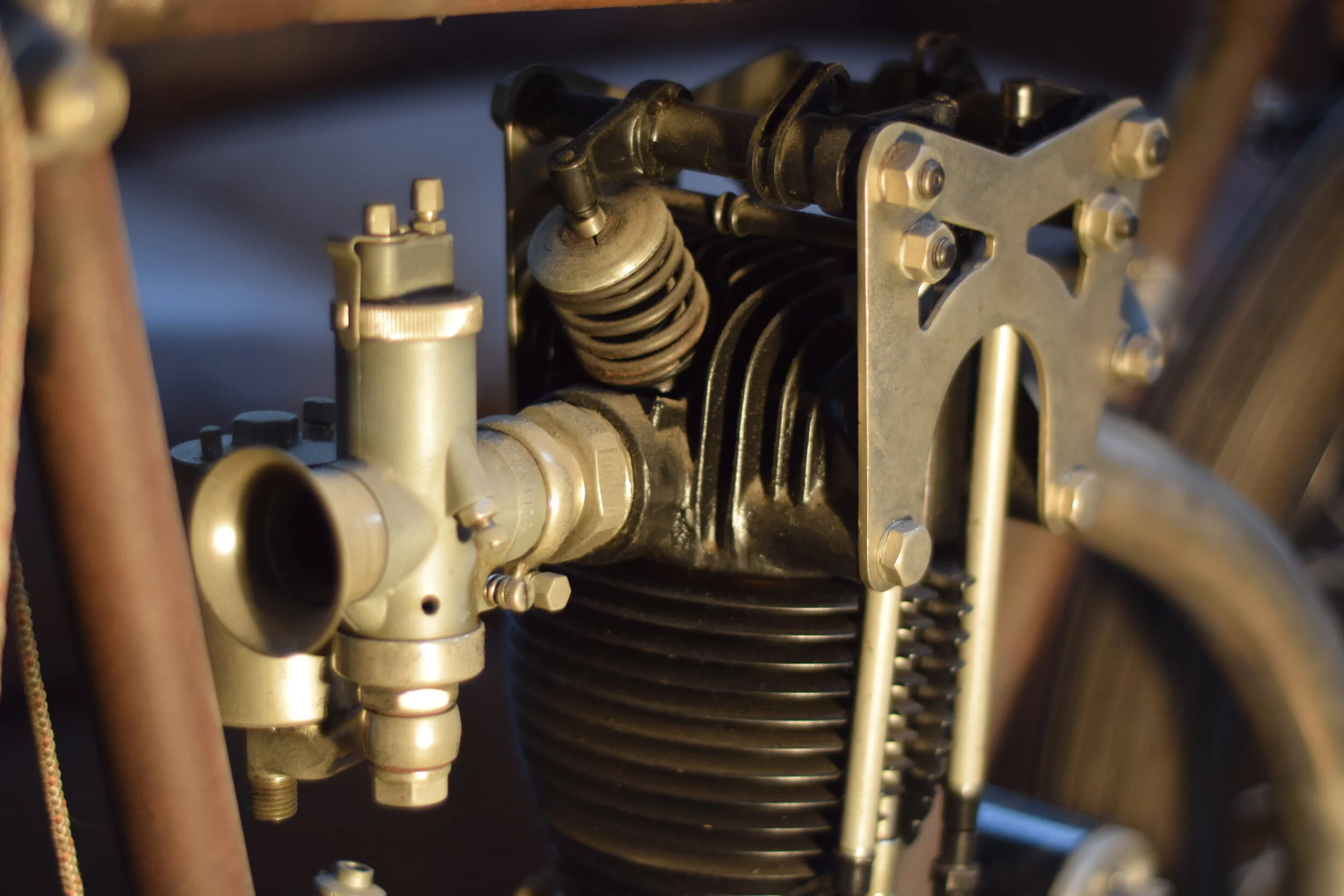

Typical OHV flat tanker engine of the 1920s - Modern convenience means chain lube rather than engine oil now more likely than not gets used to give the valve gear a squirt in wet weather. It don't come much simpler than this...

A brief flirtation with re-engineering an OHV engine of the period... soon dismissed as plain batty

The JAP speedway engine - also dismissed early on but I did consider a twin-chamber fuel tank so I could run methanol in one with a little petrol in the other for starting and cleaning out the carb at the end of a run... and for opening up for a sniff if anyone became too interested

The Works Racing 500cc Manx Engine by Patrick Walker. The sensible choice ! (Everything's relative)

Decision made then. When Patrick delivered the engine under the tonneau of his Healey 100 in the pouring rain in flat cap and waxed cotton jacket I knew I’d made the right choice!

First problem of how to fit a DOHC Manx Norton into a diamond frame seemed initially to be quite intransigent but was solved quite simply - see below. The aluminium yoke attached directly to the head bolts and was designed to add stiffness to the frame whilst allowing the engine to expand and contract without subjecting it to undue thermal stress and without the risk of the frame loads causing head gasket leaks or structural damage to the engine. This was an impossible thing to run any meaningful simulation on without turning the analysis itself into a major project and still being left with huge uncertainty about the results until they could be corroborated in practise… and so I went with good old engineering judgement. (Engineering judgement is still a major part of a design engineer’s toolbox but you’d rarely go past the initial sizing stages without simulated or calculated corroboration these days, and certainly not on something as fundamental as this.) Glad to say that after significant road and test mileage my theory seems to be holding up!

From the start the bike was laid out in CAD… this is all part of the day job after all and the engineers of the 1920s used the most advanced, convenient and useful means available… so I’ve done the same. In terms of stress and stiffness analysis (that is, computer simulation of loads, stresses and deflections/stiffness), it’s fair to say that quite a lot of this was done on the Pilgrim Precision too. Modern analysis tools are relatively quick to administer and when properly interpreted give a huge amount of information that in the past would have just not been possible to obtain without making parts (and breaking them if you were really after optimisation). One thing that fascinated me at this stage was attempting to get inside the original designers’ heads and understand the decisions they made with what they knew at the time… to me it became the most enjoyable part of the process and it felt like true re-constructive archeological engineering…

The drawings below were done by one of the team at CHD while I was working through the engineering. They’re hand drawings (hand drawn on a computer that is) using images of the CAD models and photos of the parts as reference… they were of no practical use in the design of the bike but we did them as part of an intended promotion - they’re terrific pieces of work in their own right though so I’ve included them here…

Some nice pictures...

... Really nice pictures...

How to fit a DOHC Manx Norton engine into a diamond frame...

The bike starting to come together in CAD...

Finite Element Analysis of stress, strains, stiffness... this particular image is of the Speed Pilgrim, not the Pilgrim Precision but it gives an idea...

To be continued…

Here are some more photos while I get around to writing some more… this may be a while so, in the mean-time, enjoy!

Frame and Swingarm

Forks

Gearbox